Our customers come from various sectors, including automotive, aviation, metallurgy, steelmaking, engineering, industrial services, construction, structural engineering, electrical engineering, power engineering, gas, chemical, FMCG sector, food industry, household appliance manufacturers, and numerous public institutions.

Customer: Hydro Extrusion Poland Sp. z o.o. – Chrzanów

Scope:

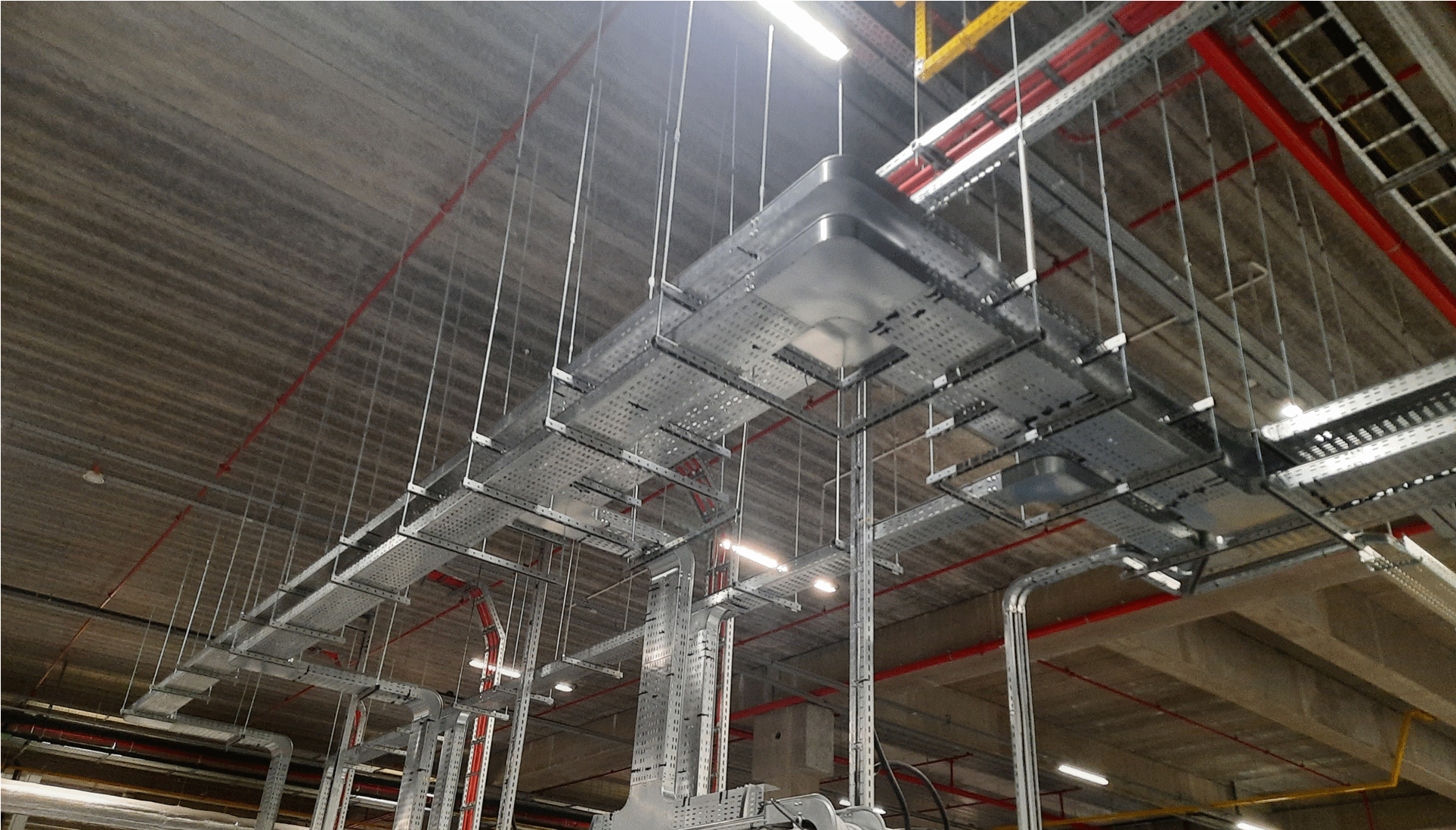

- Modernization of electrical switchgear and power installations in hall H58.

- Modernization of electrical and telecommunications installations in the administrative building of hall H58.

- Modernization of lighting installations.

- Modernization of the SSP system – Schrack Seconet.

Collaboration since 2011.

Customer: Stellantis – Gliwice and Tychy Plants

Projects:

- Electrical and automation installations for new production lines.

- Installation of LV and MV power supply systems (Schneider Electric).

- Design and installation of lighting systems.

- Design and installation of fire alarm systems.

- CCTV installation and LAN networks.

Collaboration since 2008.

Customer: Autoliv Poland Sp. z o.o. – Oława

Projects:

- Design and expansion of the LV power supply system, delivery and installation of a 1000 kVA transformer station with a 700 kVA generator.

- Modernization of lighting installations.

- Automation – DropRig project.

- Automation – camera positioning.

Collaboration since 2018.

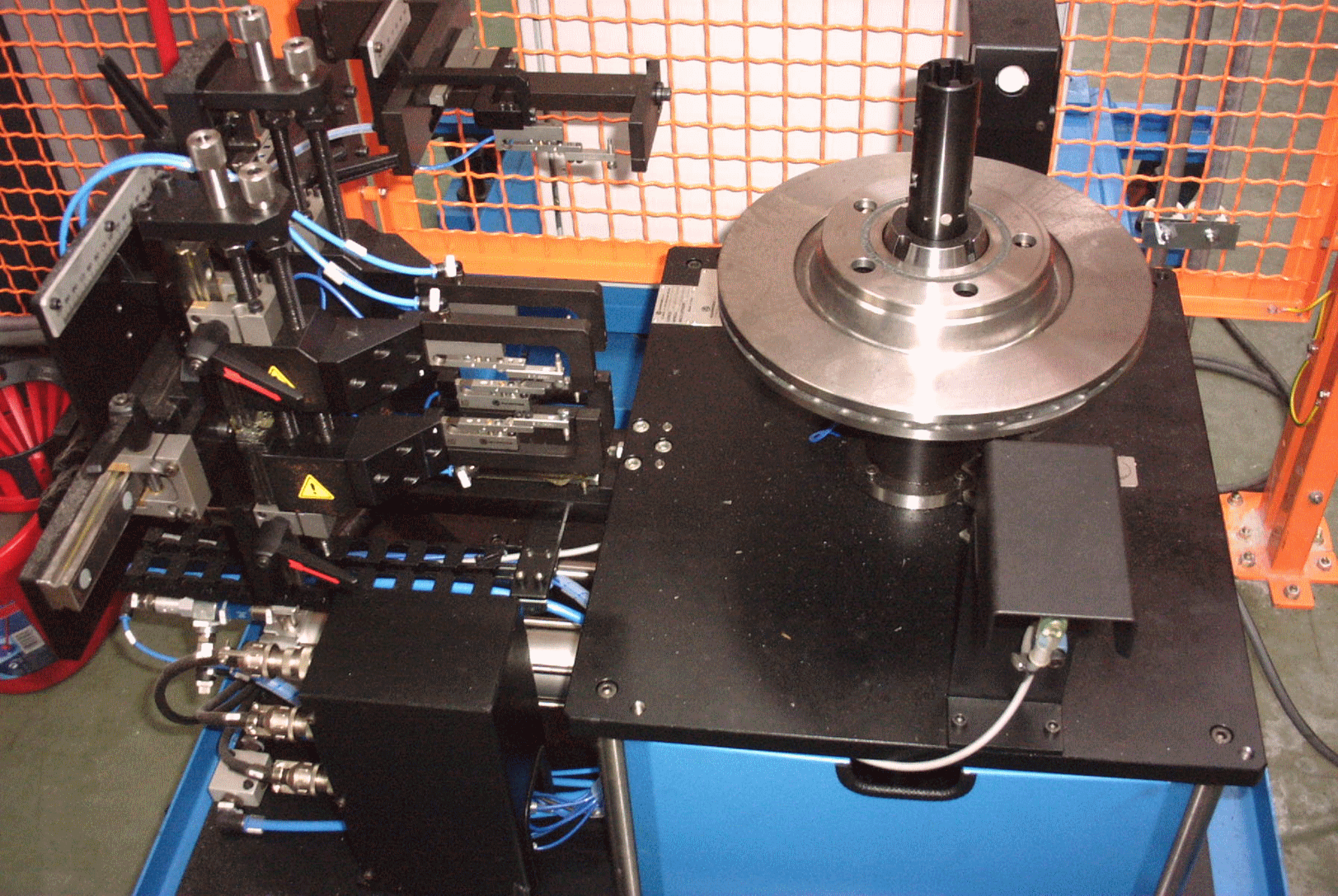

Customer: Brembo – Dąbrowa Górnicza

Project: Assembly line for Brembo brakes

Scope:

- Process, construction, and equipment design.

- Programming of KUKA robots.

- Programming of Siemens PLC.

- Design of electrical installations.

- Electrical installation.

- Mechanical installation.

- Testing and commissioning.

- Support and training of operators.

Collaboration since 2021.

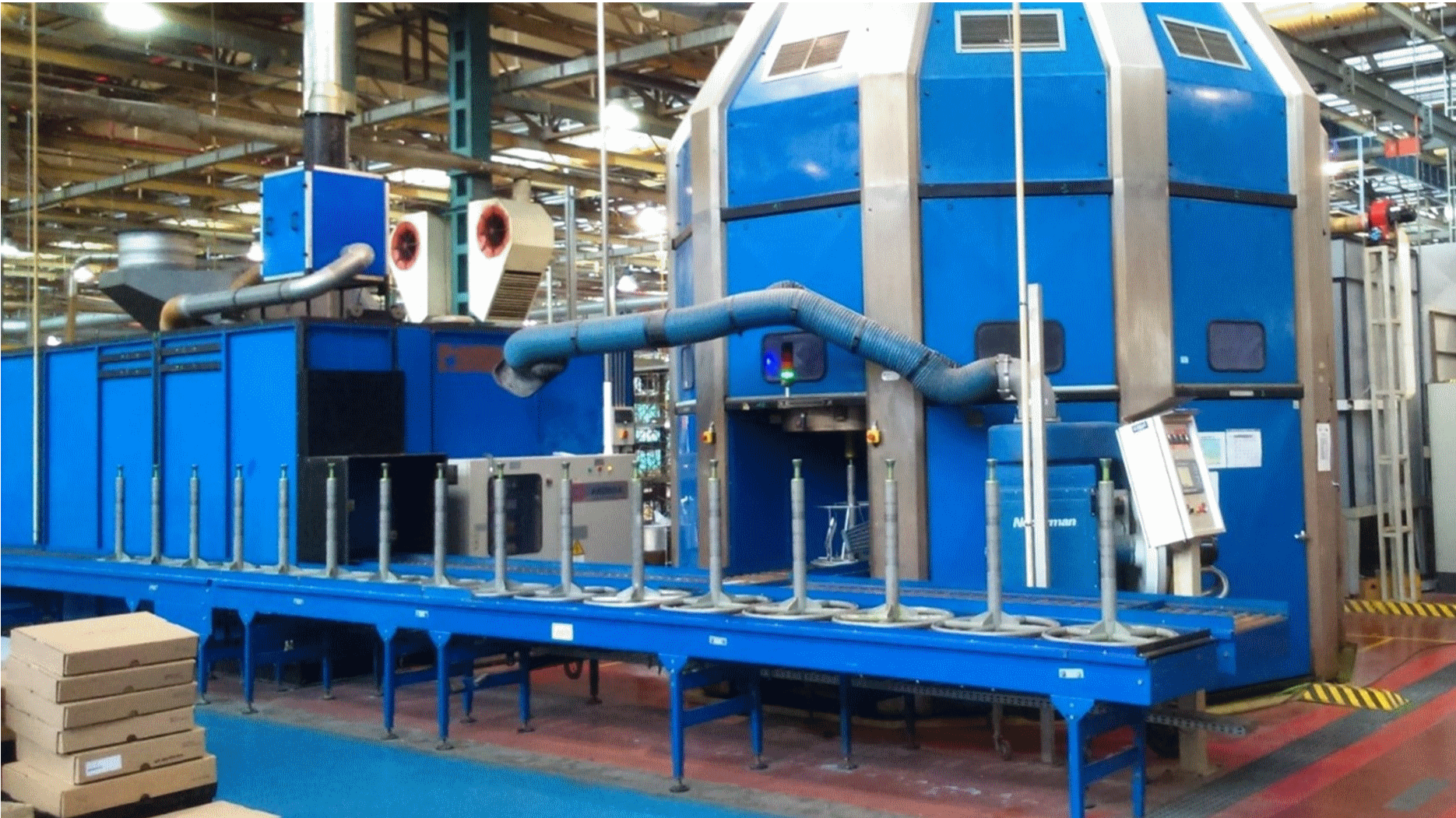

Customer: Aerospace Industry – Bielsko-Biała

Project: Modernization of a semi-automatic FPI line; Carousel

Scope:

- Development and reproduction of documentation for the modernized “Carousel” machine.

- Control-power cabinet (Siemens PLC).

- Siemens TP1200 Comfort 12’’ touch panel.

- Replacement of electrical installations.

- I/O link connection for flow meters.

- Replacement of pneumatic installations.

- Replacement of valve islands.

- Software development for the new PLC controller and HMI panel.

- Measurements and commissioning, operator training.

Collaboration since 2015.

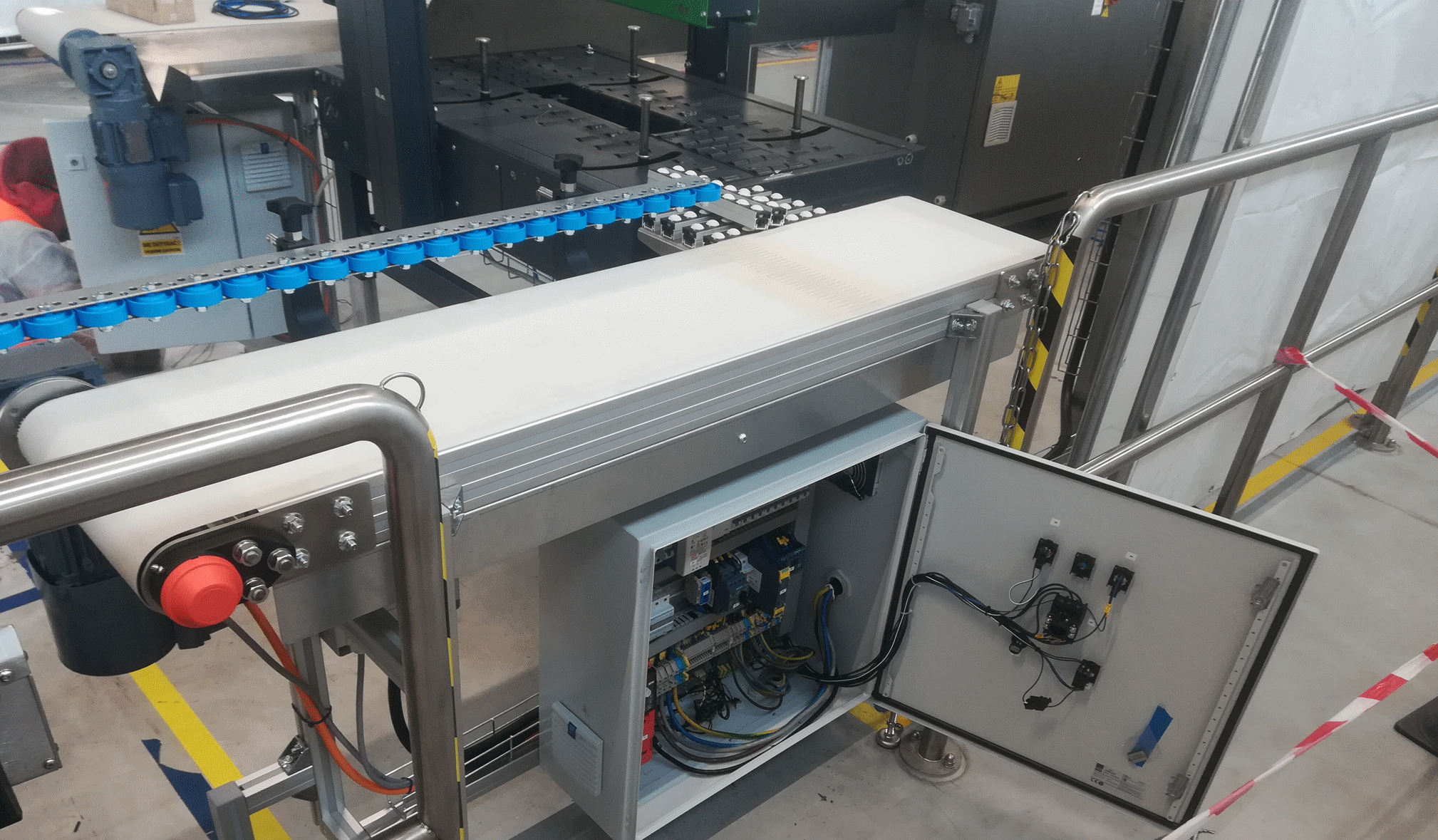

Customer: Mondelez

Project: Modernization of a production line

Scope:

- Design and implementation of conveyors, mechanics, electrical installations, and automation.

- Commissioning.

Collaboration since 2016.

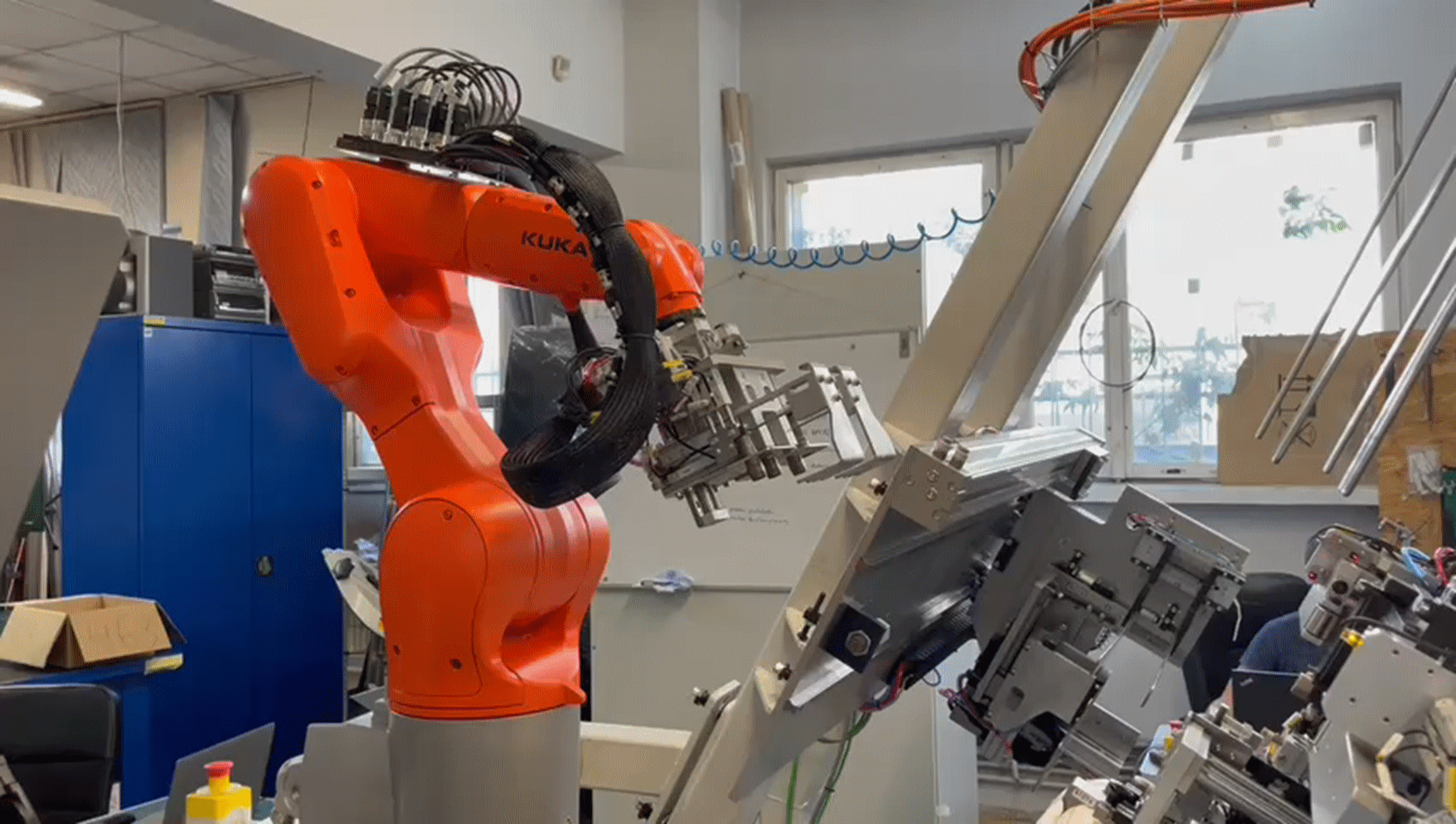

End Customer: ZF Group

Project: Prototype machine for airbag folding

Scope:

- Programming of KUKA industrial robots.

- Commissioning and testing.

- Process optimization.

Collaboration since 2021.

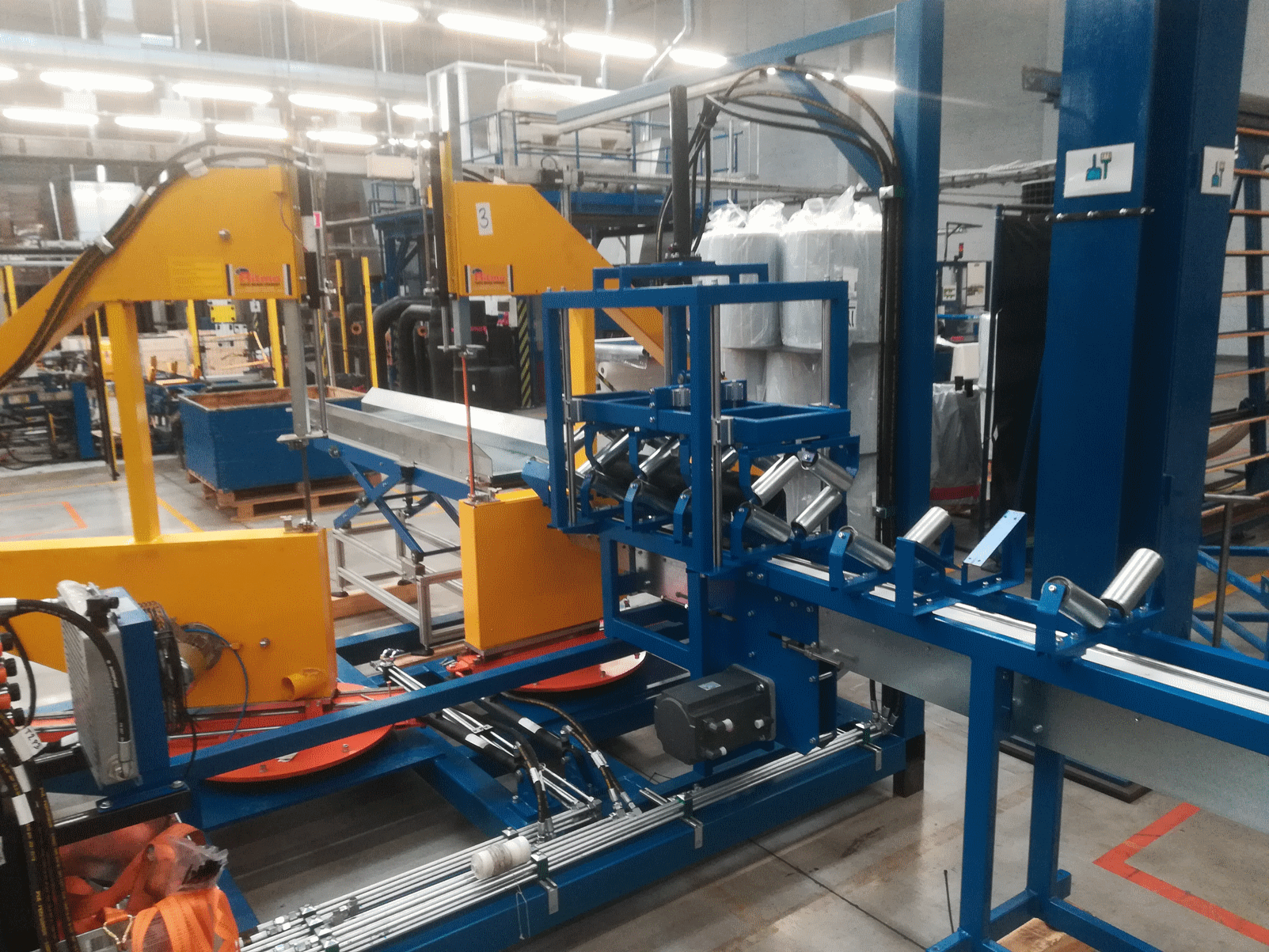

Customer: Logstor – Kingspan

Project: Cutting Center

Scope:

- Design and implementation of mechanical parts, electrical installations, and automation.

- SCADA.

- PLC programming.

- Commissioning and testing.

Collaboration since 2019.

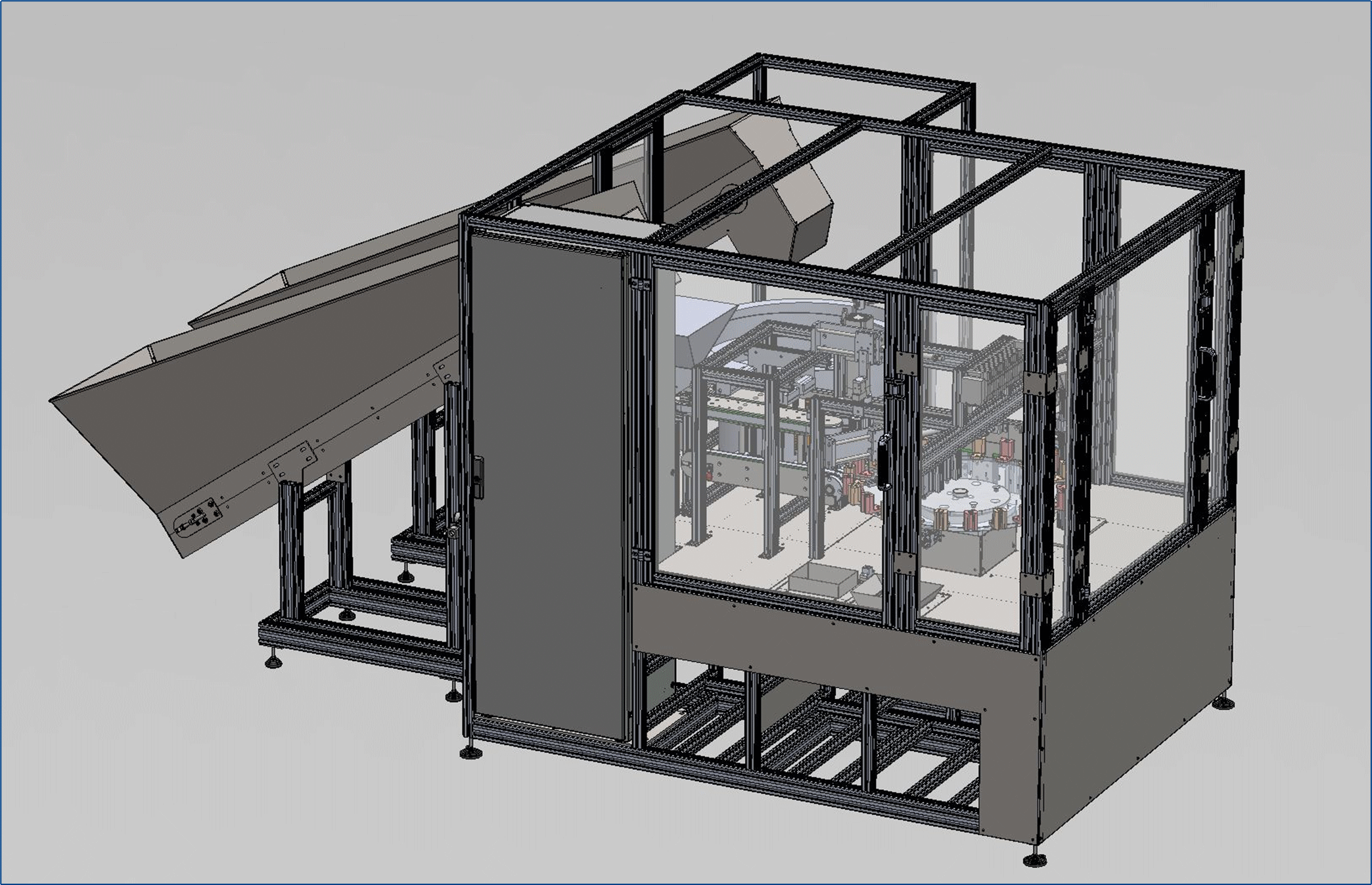

End Customer: Sulzer

Project: SULZER tube assembly equipment set

Scope:

- Design and implementation of mechanical parts and pneumatic installations.

- Commissioning and testing.

Collaboration since 2020.